- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- 简体中文

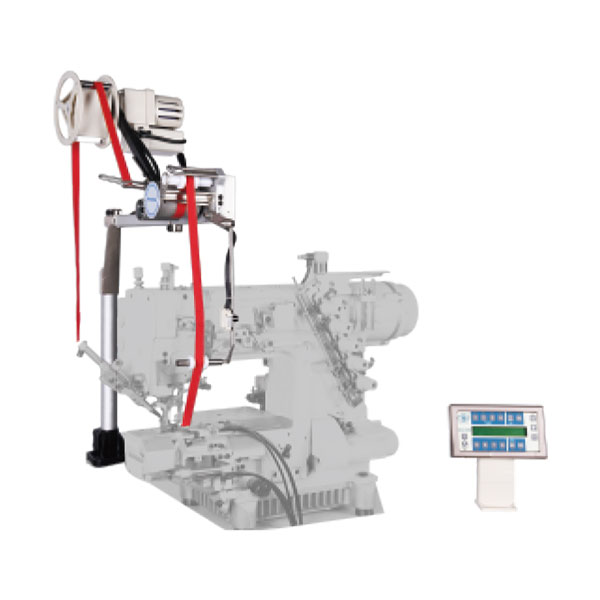

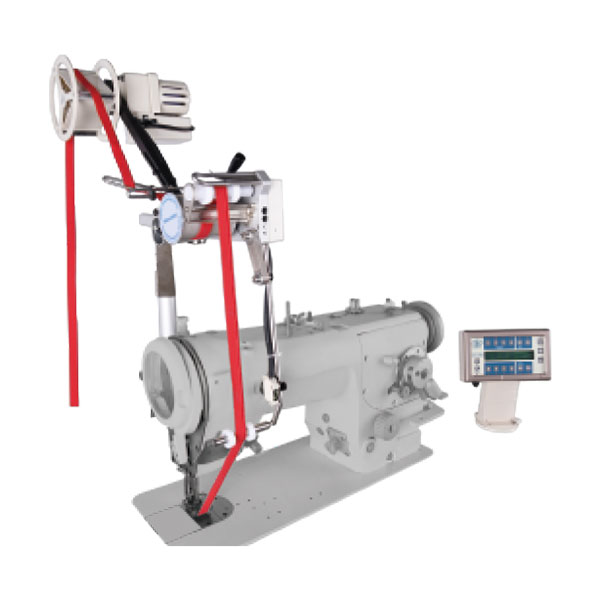

Tension Type Tape Feeder

China HD is committed to providing excellent customer service and ensuring that each customer’s needs are met. If you have any special requirements or questions about the Tension Type Tape Feeder, please feel free to contact us at any time. We will sincerely provide you with professional solutions and customized services to help you improve production efficiency and reduce operational costs.

Send Inquiry

The tension type tape feeder is a critical piece of equipment in automated production lines, with its performance directly impacting production efficiency and product quality. HD Company, with its rich experience and customization services, is able to provide clients with tension type tape feeder solutions that meet their specific needs, ensuring a perfect match between the equipment and the production line, thereby enhancing overall production efficiency and reducing operational costs.

The Tension Type Tape Feeder is a critical piece of equipment in automated production lines, with its core feature being the ability to precisely control the tension of the conveyor belt to ensure that materials are neither slipping due to insufficient tension nor damaged by excessive tension during the conveying process. This precise tension control function is achieved through a tension control system, which can adjust the tension of the conveyor belt in real-time, thereby ensuring the stability and safety of the production process.

Furthermore, the Tension Type Tape Feeder is equipped with an automatic deviation correction function, which can automatically adjust the conveyor belt during operation to bring it back to the correct running track, ensuring the continuity and stability of the production line. This automatic deviation correction function is another important guarantee for the efficient operation of the Tension Type Tape Feeder.

By integrating an intelligent monitoring system, the Tension Type Tape Feeder is capable of real-time monitoring of its own operational status. Advanced sensors and data processing technology are employed to collect and analyze various parameters of the equipment, such as speed, tension, temperature, and vibration. This system not only enhances the stability and reliability of the equipment’s operation but also effectively reduces production interruptions caused by equipment failures, significantly improving production continuity. Additionally, it provides real-time and accurate data support to production managers, helping them make more informed decisions and further enhancing overall production efficiency

Applications:

Material Conveyance on Production Lines: In automated production lines, tension type tape feeders are used to precisely control the tension of the conveyor belt, ensuring the stable and efficient transfer of materials during the conveying process.

The tension type tape feeder plays a pivotal role in modern industrial automation, not only enhancing production efficiency and reducing labor costs but also ensuring the stability of product quality. With continuous technological innovation, the tension type tape feeder provided by HD Company continues to improve in performance and functionality, injecting new momentum into the development of industrial automation.